Automatic CNC Polishers Grinders

- Home

- Automatic CNC Polishers Grinders

GUARANTEED QUALITY OF POLISHED SURFACES AND SERIES REPEATABILITY

Despite many predictions about the decline in the furniture market of high-gloss coatings, they still enjoy great interest. The answer to ready-made automatic solutions in the field of production is the offer of ICA Polska, which is the sole distributor of Coner polishing machines.

The machine is responsible for reducing the amount of work and eliminates many problems that often involve standardizing production. Usually, the problem is the repeatability of gloss quality and the polishing process itself. Human participation is not without significance in the cycle. In addition to repeatability, strong emphasis should also be placed on accuracy and precision, which is very important in the production process.

The answer to the market need was to develop a machine that is automated and the process itself requires as little human intervention as possible with high repeatability. It is worth mentioning that the device is a response to customer needs. Come on, it also happens that people who have never polished take their first steps on this type of machines.

The basic conditions of polishing were based on the possibility of significant regulation in the field of: polishing time, pressure force, rotational speed or even such an important element of polishing to a given edge point, commonly referred to as margins. All these and other important parameters can be freely configured.

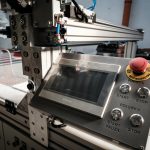

At the same time, we develop our own individual cycle based on the hardness of the varnish, color or desired gloss. Interestingly, the polishing device can successfully work as a grinder or a brilliant machine, which definitely distinguishes the machine from competitors’ products. The most important element, however, remains human participation, reduced in this case to a minimum. The undoubted advantage is the compact dimensions of the device and the possibility of polishing different colors with a quick change of the medium (in this case, a sponge is usually recommended as a polishing medium). All these advantages mean that the devices have found buyers among the leaders of high-gloss production, but also among small companies.

The process of implementing the device gives you the opportunity to transfer your preferences or polishing preferences, and often it is a simplification of the production process itself. At the same time, it remains a pleasant surprise for people who struggle with problems in the polishing process on a daily basis.

Technical data

1. Maximum width of the furniture front: 800mm or 1100mm (depending on the version)

2. Dimension of the conveyor belt: 1600 x 800mm or 1600 x 1100mm

3. Two roller tables 800 x 800mm or 1100 x 1100mm

4. Material holder: vacuum table

5 Polishing head: 2 kW three-phase motor controlled by an inverter

6. Grinding head – optional – 12,000 rpm three-phase motor + Festool ETS 150/3

6. Longitudinal oscillations of the head by the digitally controlled motion of the conveyor belt (linear and oscillating movement)

7. Head movement: pneumatic linear drive

8. Control: PLC with touch LCD operator panel

9. Measurement of the size of the furniture front: optical and ultrasonic sensors

10. Maximum power consumption: 2.5 kW