CNC Hot Wire Cutters for Precision Foam Cutting

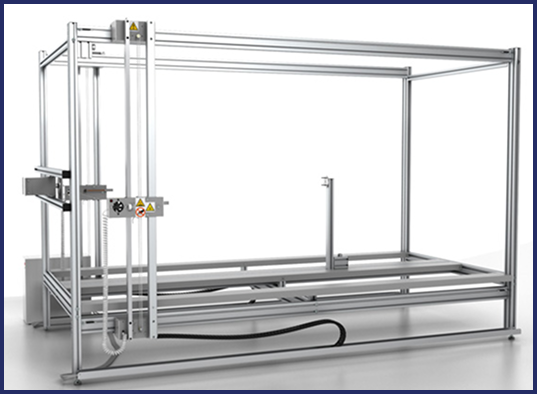

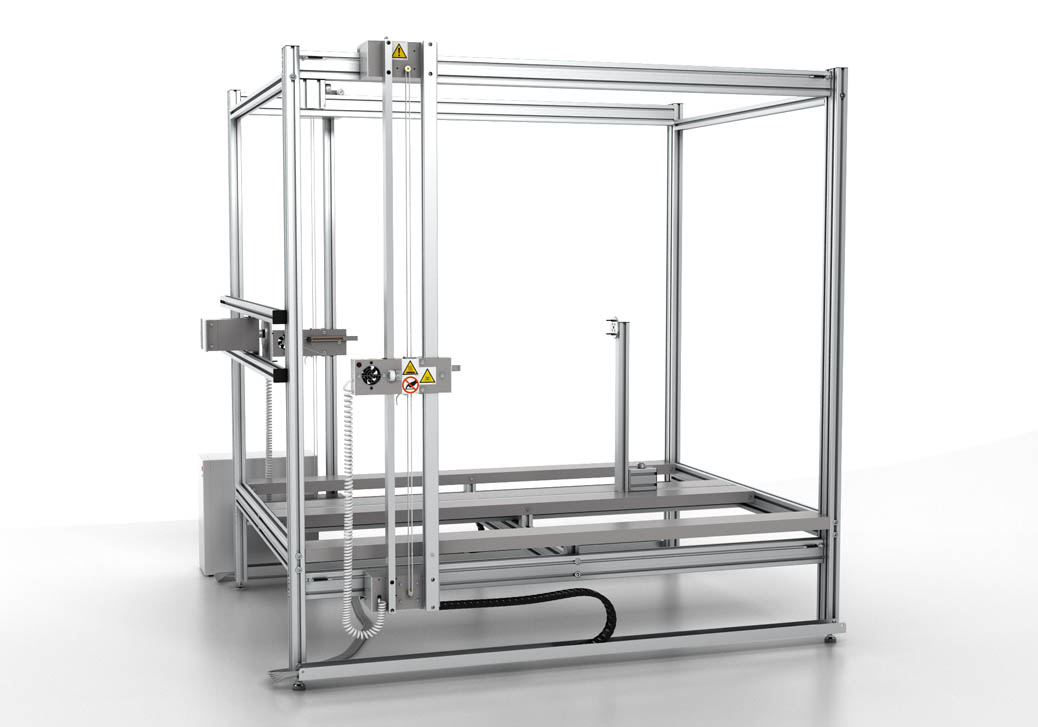

Bring your creations to life with the ThermoCut Pro hot wire cutter, a must-have piece of equipment for professionals who need accuracy and speed. This precision foam cutting machine is designed to perform simple cuts and very detailed 3D modeling with a high degree of accuracy and precision.

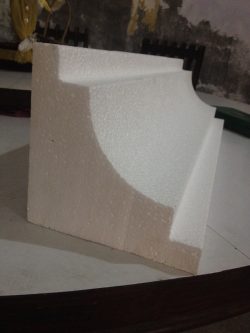

The CNC hot wire foam cutter is specially designed for styrofoam and polystyrene foam upto a density of 60 kg/m³. This enables the manufacturer to produce complex models and decorative elements with sharp edges and smooth surfaces. For designs with circular or curved components, the turntable hot wire cutter offers additional convenience.

The ThermoCut Pro is a heavy duty foam cutting machine available in KSA and GCC, and like any other heavy-duty machine, it helps increase productivity. In this case, it helps save time and material waste while improving the accuracy of the professional results achieved. It is the solution to everything for signage and architectural design companies as they can now turn all their creative ideas into real life objects.

Features

High-Precision Cutting

Delivers accurate cuts with minimal material waste.

User-Friendly Control

Easy-to-use interface for quick setup and operation.

Durable Build

Strong construction for long-lasting performance.

Independent Access Control

Allows separate operation of machine sections for safer, more efficient workflow.

Capable Wire System

Delivers consistent heating for smooth, accurate cuts across varying foam densities.

Material Versatility

Compatible with multiple materials and applications.

Fast Operation

High-speed cutting without sacrificing quality.

Low Maintenance

Simple upkeep with minimal downtime.

Turn Table for Lathe

Enables precise 360° rotation for cylindrical and complex foam cutting.

Available Models

| Model | Pro 35 | Pro 60 | Pro 120/150 | Pro 240 | Pro 300 |

|---|---|---|---|---|---|

| X Workspace (Length) | 130 cm | MINI 130 cm MIDI 240 cm MAX 300 cm |

MINI 130 cm MIDI 240 cm MAX 300 cm |

MINI 130 cm MIDI 240 cm MAX 300 cm |

MINI 130 cm MIDI 240 cm MAX 300 cm |

| Y Workspace (Height) | 60 cm | 130 cm | 130 cm | 130 cm | 130 cm |

| Cutting Wire Length | 35 cm | 60 cm | 130/150 cm | 240 cm | 300 cm |

| Resistant Wire Diameter | 0.25 mm | 0.35 mm | |||

| Forming Wire Diameter | 0.9 mm | ||||

| Resolution | 0.01 mm | ||||

| Max. Shift Speed | 2000 mm/min | ||||

| Max. Working Speed | 2000 mm/min | ||||

| Resistant Wire Cooling | 2 Cooling Fans | ||||

| Number of Stepping Motors | 3 | 6+1 | |||

| Cutter Construction | Reinforced Aluminum Profiles | ||||

| Power Supply | 220V/50Hz 110V/60Hz | ||||

| Power Consumption | 150 W | 200 W | 250 W | 750 W | 950 W |

| Interface | Port USB | ||||

| Forming Wire | Option | Standard | Option | ||

| Revolving Table | Option - S10 | Standard - S150 | Option - S150 | ||

| Lathe | Option | Standard | Option | ||

| Independent Arm Motion "Perspective" | Unavailable | Standard | |||

| Additional Cutting Wires | Unavailable | Option | |||

Applications

Our CNC hot wire foam cutter is made for versatility. It supports industries that need both precision and creativity. Whether you’re using a hot wire styrofoam cutter for signage, a turntable hot wire cutter is for curved architectural elements, or a heavy-duty foam cutting machine for large-scale production, ThermoCut Pro meets your needs with accuracy and efficiency.

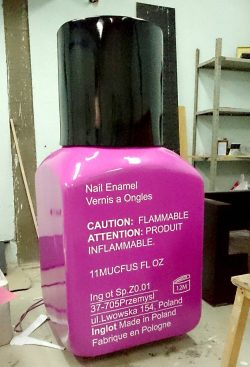

Advertising & Signage

Wide-format outdoor displays

Decorative 3D letters and logos

Trade graphics and branding elements

Trade-post and exhibition stands

Architecture & Scenic Design

Entrances, portals, and colonnades

Cornices, keystones, and column features

Interior design accents

Theatre and film set pieces

Other Uses

Casting molds and packaging prototypes

Lightweight furniture parts

Pipe coverings for insulation or design

Acoustic panels and sound screens

General 3D modeling and custom designs

FAQ About CNC Hot Wire Cutters

A CNC hot wire cutter is used to cut and shape foam materials with precision. It is commonly applied in Packaging, constructions, architectural models, Advertising, Signage, Life Size Sculptures, indoor and outdoor decoration, interior and fitouts.

Our CNC hot wire cutters can cut EPS, XPS, EPP, and other types of foams with accuracy and clean edges.

These machines operated with high cutting precision, typically up to ±0.5 mm, ensure smooth and constant results for industrial applications.

Laser cutters can burn or damage foam, while CNC hot wire cutters are specifically designed for foam cutting, offering clean, safe, and more precise results.

Yes, CNC hot wire cutters are designed to cut insulation foam precisely and safely. Our machines also includes ventilation and safety features to ensure operator protection.

Request Your Quote Now!

Get in touch today for a free, no-obligation quote for your own

customized machinery for a wide range of industries. Feel

free to reach out for any queries. We’d be happy to help!

Call us

+971-50-9942579

Office Address

KASHIF SAEED GENERAL TRADING LLC,

P.O BOX 238071, DUBAI, UAE