CNC Milling Routers

Features

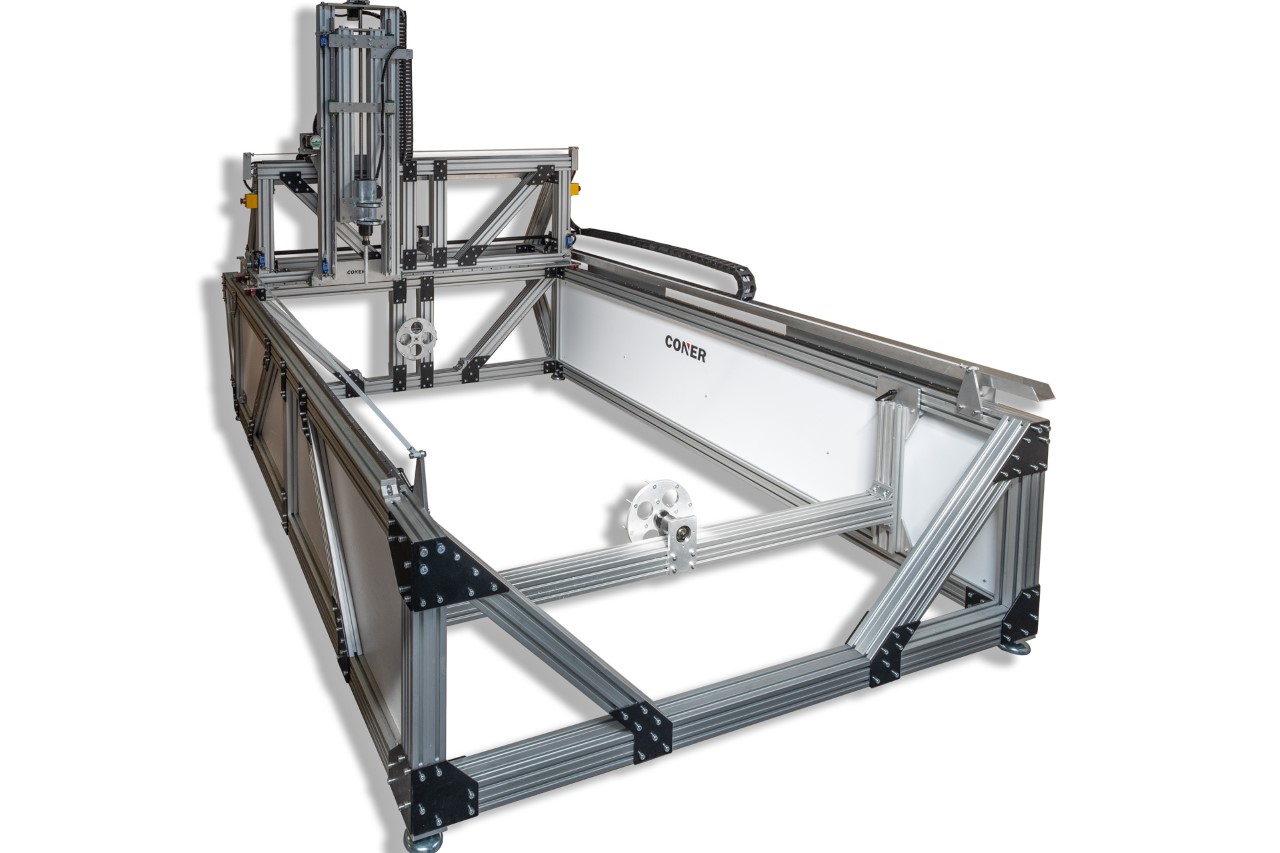

Working Area

X: 240 cm • Y: 125 cm • Z: 60 cm (optional 70 cm)

Rotary Axis

360° continuous rotation

Structure

Heavy-duty rigid frame for vibration-free cutting

Software

MACH3 & DESKPROTO

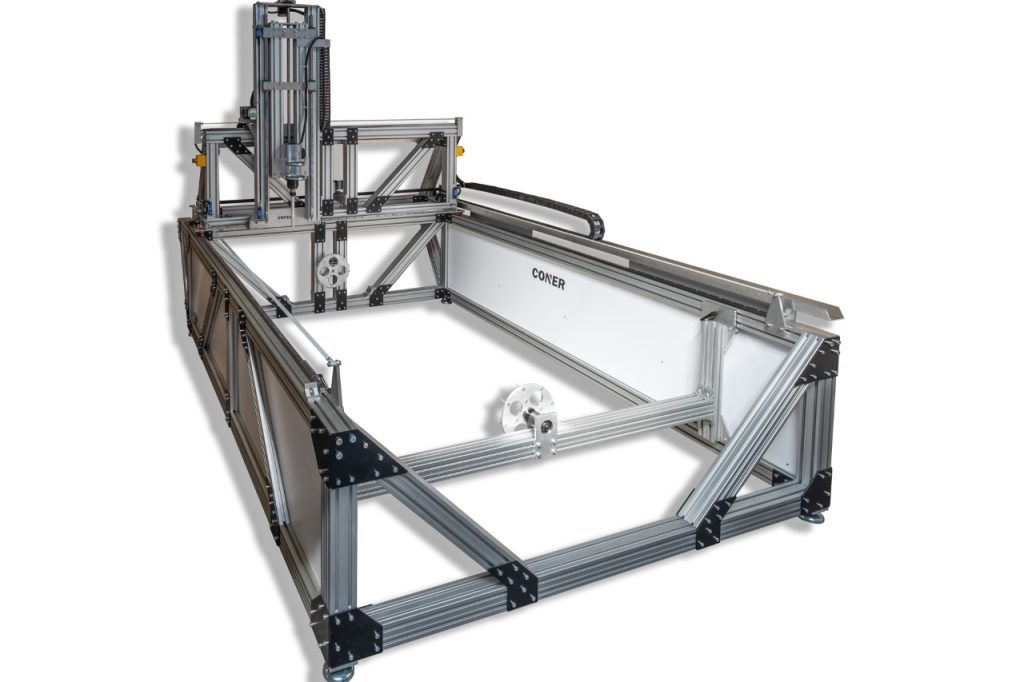

Spindle

2.0 KW Air-Cooled Spindle

Control Panel

Convenient, user-friendly operation

Toolpath Creation

Easy design setup via Deskproto

File Compatibility

Supports .STL file format

Product Specifications

This 4 axis milling machine uses a rack and pinion system on the X and Y axes and a ball screw on the Z axis for smooth, precise motion. Powered by Sanyo-Denki stepper motors with planetary gears, the CNC milling machine provides reliable performance and torque. Communication with the PC is handled via Ethernet, and the system operates seamlessly with Mach3 control software, making it a highly efficient CNC automated milling router.

Applications

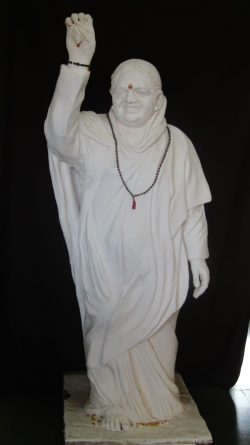

- Ideal for architectural scale models, mold patterns, sculptures, and event props.

- Delivers smooth surface finishes with minimal sanding required.

- Capable of producing both large-scale and fine-detail designs in styrofoam.

- Supports 3D, rotary, and deep cut operations for complex shapes.

CNC Milling Router FAQ

CNC Milling Routers are computer-controlled machines designed to cut styrofoam with precision. The machine uses a four-axis system including a rotating axis to produce smooth, complex 3D shapes. It is especially helpful in the creation of architectural models, mould patterns, sculptural pieces, and props for events.

The CNC Milling Router is 240 cm x 125 cm in size with a 60 cm Z Height, which can be extended to 70 cm. The rotary axis allows for 360-degree continuous rotation. It is made of a rigid, heavy frame to reduce vibration. The spindle is 2.0 kW and air-cooled. It uses rack-and-pinion on X, Y, and Z axes and a ball-screw on the Z. Sanyo Denki steppermotors and planetary gears power its motion. It supports Mach3 software and DeskProto.STL files.

The machine was designed to meet the needs of industries such as packaging, architecture, and events that need detailed prototypes. This machine produces large-format models, props, and molds in styrofoam with a smooth finish that requires little or no sanding.

This CNC Milling router is designed for soft materials like styrofoam. It has a large working area and rotary-axis capabilities. A CNC Mill, which is usually built to cut harder materials, such as metals, provides deeper cuts and greater rigidity. Standard routers lack the precision and can’t control multiple axes of a CNC.

Mach3 is used for setup and control. The machine accepts the.STL file format is common for CAD/CAM workflows.

It uses ball screws for vertical movement. The Z-axis is powered by rack and pinion drive. The system utilizes Sanyo Denki stepper motors with planetary gears and communicates via Ethernet to ensure reliable control.

Mach3 is the control software for CNC Milling Routers. It interprets G-code instructions from CAD/CAM design and executes with precision.

The machine is equipped with a heavy-duty, rigid frame, which minimizes vibration. It ensures accuracy in cutting and smoother surface finishes. This reduces the need for sanding.

Request Your Quote Now!

customized machinery for a wide range of industries. Feel

free to reach out for any queries. We’d be happy to help!

Call us

+971-50-9942579

Office Address

KASHIF SAEED GENERAL TRADING LLC,

P.O BOX 238071, DUBAI, UAE